iBulk Munson Rotary Drum Screen

Perfect results with the iBulk® Munson® Rotary Drum Screens to separate solids from waste streams without clogging.

iBulk Munson Rotary Drum Screens allow you to remove solids from industrial and municipal waste streams, and recover solid product from process streams, at rates from 760 to 17,600 litre/min.

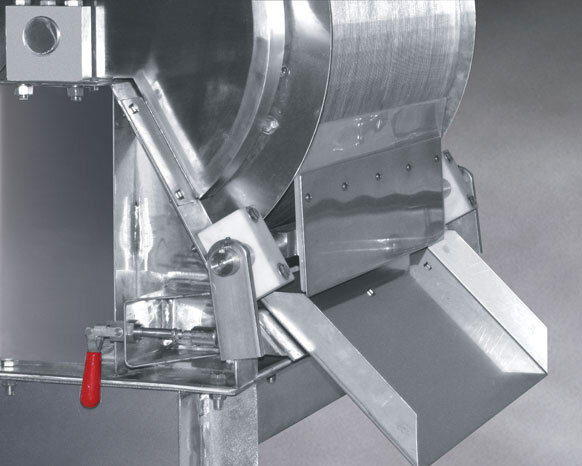

The rotary screen consists of a horizontal cylinder with durable wedge wire screening, a variable speed drive, head box, discharge chute and support structure. It’s design allows for reduced floor space and headroom requirements compared with non-rotating equipment of equivalent capacity.

An optional variable-speed drive allows adjustment of drum rotation speed to achieve maximum dewatering effectiveness. The wedge wire screen of the cylinder is available in many orifice sizes from 50 micron to 2.75 mm.

The rotating drum is the only moving part, minimising operating and maintenance costs.

FEATURE OF THE ROTARY DRUM SCREENS

Removes solids from waste streams

Recovers solid product from process streams

Rates from 760 to 17,600 liter/min

Prevents blinding or clogging of screen

Removes moisture levels to 20 percent range

Variable-speed drum rotation maximises effectiveness

Full-length water knife dislodges trapped solids

Wedgewire screen apertures 50 micron to 2.79 mm

Handles oily, greasy, fibrous or resinous matter

Drum is the only moving part, reducing cost, maintenance

Cost, maintenance

New self-cleaning arrangement

Drier recovered solids

Reduced floor space requirements

Low headroom requirements

Fewer moving parts

Variable speed drive

Low operating & maintenance costs

Low initial investment

TYPICAL APPLICATIONS AND INDUSTRIES

Typical applications for the iBulk Rotary Drum Screen include:

Separation of various solids and sludges from municipal and industrial wastewater

Food processes

Pulp and paper production and rendering processes

Removal of extruded pellets from cooling baths

Separation of debris from any variety of plant and equipment-cleaning processes

Separation of solids from wastewater and sludges

Food process effluent

Pulp and paper

Rendering processes

Thickening of sludge/scum

Separating grit from rock

Removal of fines

Extruded pellet cooling baths

Car wash rinse water cleaning

Tannery effluent solids removal

Separation of seafood processing rinse water

Hazardous solids removal from remediation sites

Numerous other solids removal, recovery and cleaning applications