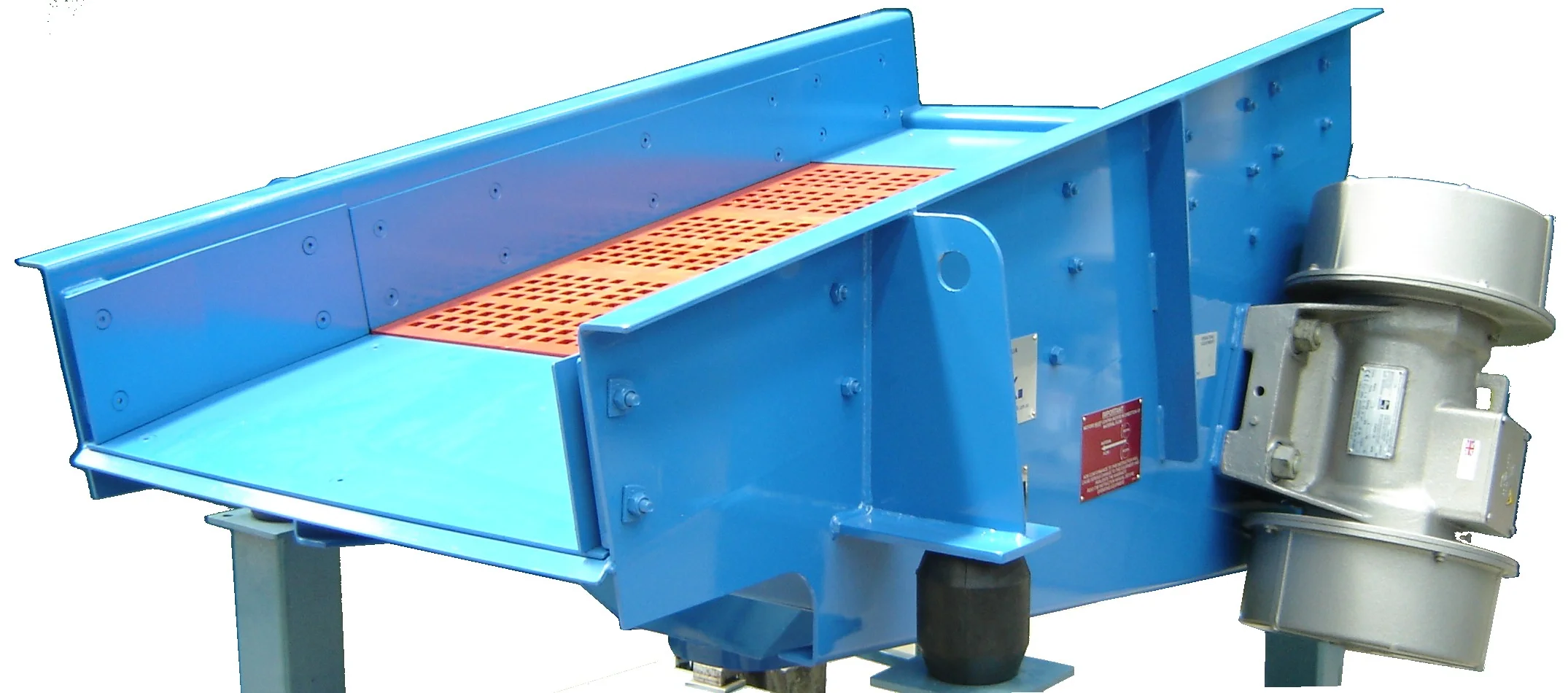

iBulk Direct Drive screener

The iBulk Direct Drive screener uses a conventional trough design combined with screen panels of woven wire to separate one or two grades of product.

The screener discharges centrally or to either side.

Advantages

Low maintenance requirements.

High capacity screening

Easily enclosed

Dust Light

Suitable for high-temperature application

Installation

Installation being horizontal or inclined to suit specific application.

Screen media can be varied from woven wire to polyurethane panels.

Direct Drive Screens are generally mounted on rubber springs and for heavy duty or High-Temp applications on steel coil springs. This makes them freely vibrating units transmitting minimal vibration to surrounding structures. Alternatively, the screeners may be suspended (steel ropes off eyebolts) on rubber compression springs. They do not require special foundations.

High vibration damping may be achieved by using soft springs with high static strength.

Applications and Industries

Direct Drive screens are truly versatile and have been use in the following applications.

Lump removal from a feed of raw material like Urea in fertiliser or bath in an Aluminium Smelter.

Rough aggregate screening to scalp off oversized particles whilst keeping a dust tight enclosure.

High temperature product transfer and separation.

Long trough conveying up to 8 metres with multiple size separations.

Withdrawing bulk material from bins and hoppers

Dewatering screens

Some of the industries that the screeners have been used in are:

Smelters

Mining

Aggregate

Chemical