Particle Size Reduction Solutions

iBulk® offers industry leading Bepex® Size Reduction Equipment, providing solutions for a wide range of applications.

The iBulk® Bepex® range of size reduction mills offer the best solution for every process and application – dry, wet, coarse or fine.

iBulk’s versatile range of fine grinding machines take on the most complex particle size reduction jobs, with multiple grinding zones, internal classification, rotor speed controls and different screen sizes and shapes.

Our coarse grinding mills are capable of solving the toughest grinding applications, from large rubber bales, frozen blocks of food, or lumpy mixes we offer the flexibility to meet all your final product requirements.

With over 30 years of industry experience and know how iBulk will help select the right size reduction equipment for your needs. Our size reduction equipment can be tailored to your industrial process for optimised

performance and value.

SIZE REDUCTION EQUIPMENT INCLUDE

Dry, wet, coarse or fine – iBulk has the industrial process equipment solution to meet your needs:

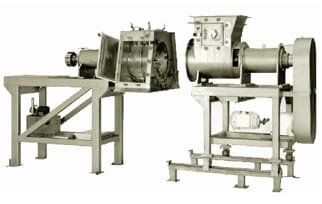

Extructor – for crushing and grinding of frozen blocks or barrels of bulk materials

Rubber Chopper – for shredding and grinding of bulk rubber, plastic, and adhesive

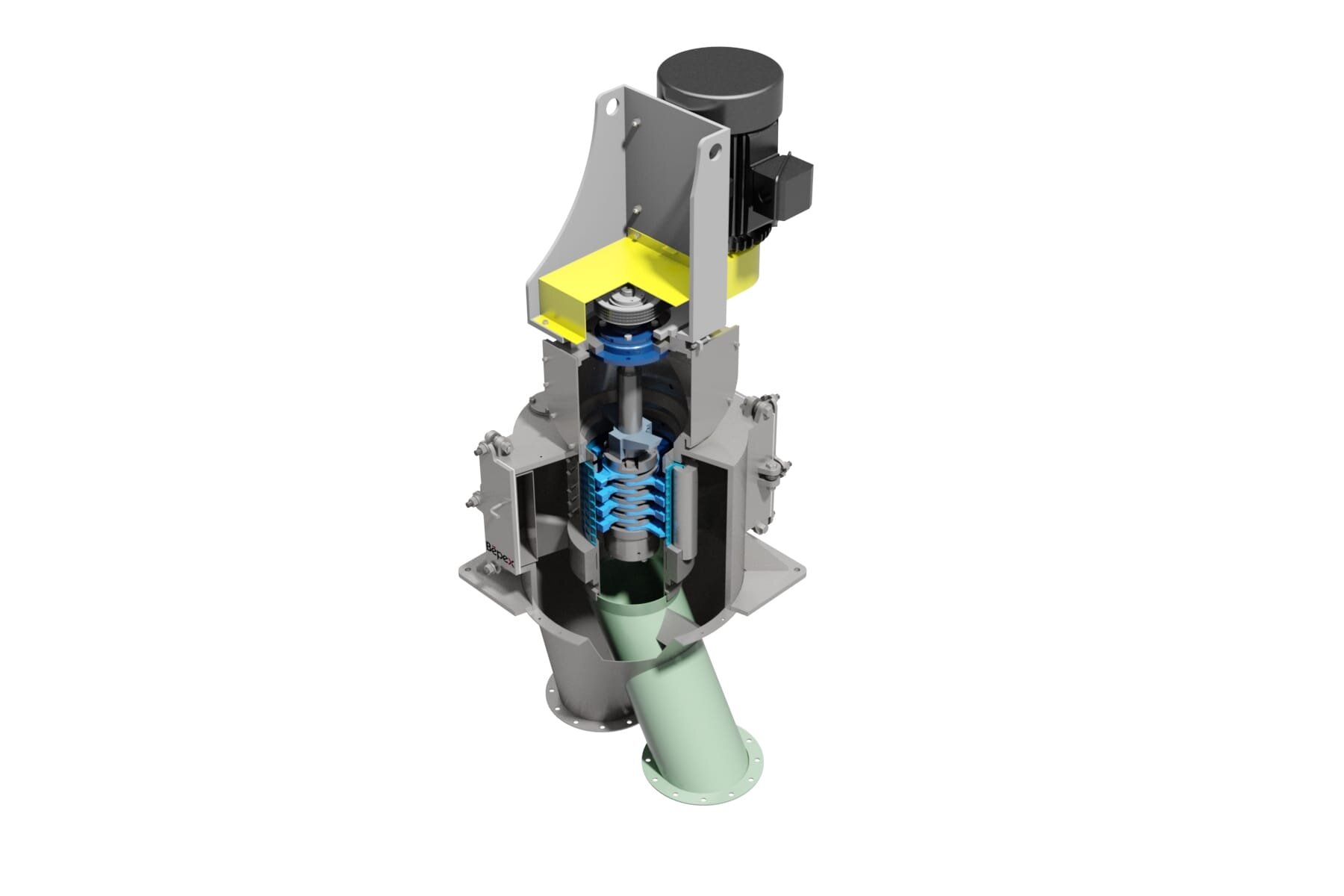

Pulvocron – an air classifying mill for fine grinding and flash drying

REH Disintegrator – for coarse crushing and fine grinding in a single step

RD Disintegrator – for mixing and delumping of slurries, pastes, liquids, and resins

RI Disintegrator – for mixing and delumping of slurries, liquids, resins, and pastes

RH Disintegrator – for emulsifying and suspending wet mixtures

RA & RP Disintegrators – for grinding, shredding, delumping, or pulping of wet and dry feeds

We can provide a single technology for one-step particle size reduction, or incorporate those technologies into a complete size reduction system as required by your specific industrial process application.

All iBulk® Bepex® size reduction equipment is available for full-scale and pilot-scale testing. The Bepex innovative Process Development Center and our dedicated aftermarket process, and tailor-made designs ensure your specific size reduction process needs are achieved.

TYPICAL APPLICATIONS AND INDUSTRIES

Typical applications for the iBulk Size Reduction Solutions:

Versatile size reduction technology capable of grinding, shredding, delumping, or pulping of wet and dry feeds

High-intensity mixing and grinding

Ultra-fine grinding of grains and pulses

Homogenising of powder streams

Grinding of food fibers during food processing

Pulverising of minerals during mineral processing

Chopping of bulk rubber and polymer

Delumping of large agglomerates

Final sizing in material granulation systems

Processing food / fresh and frozen food blocks

Industrial wet grinders to produce slurries or pastes

Coarse and fine grinders for high-moisture materials

Shredding of high moisture and/or oil materials

Defiberising, dissolving, dispersing of slurries

Fine pulping of soft fruits and vegetables

And many others