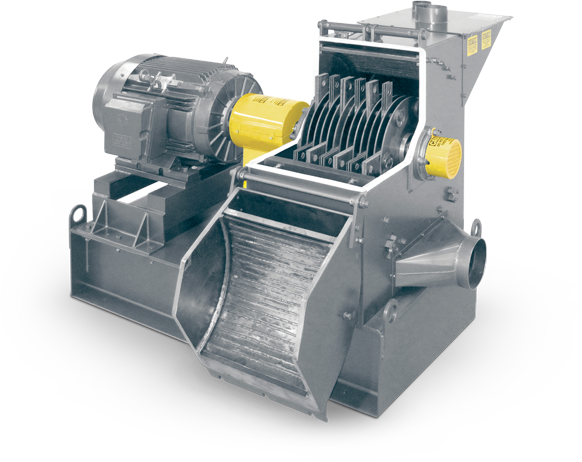

iBulk Munson Hammer Mills

The iBulk® Munson® Hammer Mills are designed to reduce an impressive range of friable, non-friable and fibrous materials into particle sizes from coarse pieces down to 200 mesh — efficiently and at high rates.

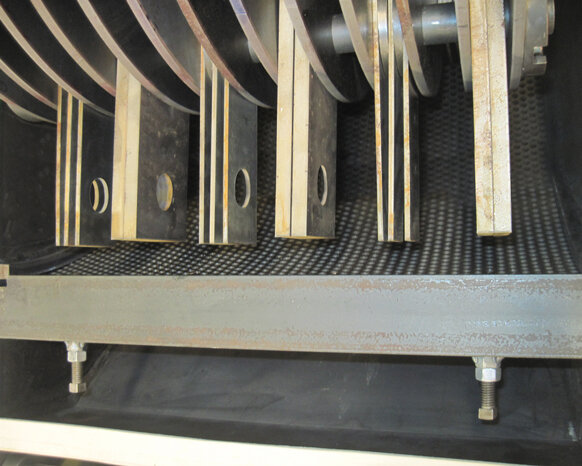

For general grinding, standard equipment consists of alternating heavy and light hammers. The type, number and arrangement of hammers can be varied readily to optimise performance according to material characteristics. All corners of the hammers are stepped as standard, offering three-times the cutting edges of square-cut hammer tips for greater efficiency.

The mill units are configured with a large safety-interlocked door, providing rapid, unobstructed access to the mill case interior.

iBulk is the leading distributor of Munson’s equipment in Australia and offers tailor-made solutions and expert industry know-how. iBulk’s ability to develop custom design and 3D models of the actual machines provides clients with a detailed visualisation of their specific solution.

APPLICATIONS AND INDUSTRIES

The Munson Hammer Mills are typically used in these industries and applications:

Animal feed, biomass, corn

Batteries

Bulk spices, herbs, food products

Carpet and carpet grindings

Ceramics, cement, lime

Chemical products in bulk and solid form

Coal, slag

Glass bottles, cullet, syringes

Grains, seeds and shells

Filings, turnings, shavings

Mining materials

Paper/newspaper

Plastic parts, housings, reinforced composites

Roof shingles

Rubber-steel-cord separation

Storage media, hard drives, PCBs, phones/electronics of all types

Sugarcane

Wood bark, scrap, chips, shavings, particle/fibre board, hogged scrap

FEATURES OF THE HAMMER MILL

Large, obstruction-free product feed opening

Peripheral hammer velocity from 1,100 to 7,300 m/min together with hard-faced breaker plates and perforated bed screen,

reduces a wide range of material types and sizes at high ratesGreater output per horsepower/kilowatt than many other types of mills (Horsepower range from 50-250)

Hardened steel hammers with "stepped ends" offer three-times the cutting edges of square-end hammers

Four-way reversible design allows all stepped hammer corners to be utilised before replacing

Radiused bed screens with perforations from 0.8mm to 76mm

Lower transition for pneumatic removal of reduced materials

Hinged mill case door provides unobstructed interior access for rapid inspection and changing of breaker plates,

screens and hammersMachined mating surfaces of door and mill case provide dust-tight operation

Directly-coupled drive

Welded heavy-plate carbon steel mill case maintains precision alignment of dynamically-balanced rotor assembly despite extreme impact

and high loads of demanding applications